This article asks: What equipment is needed for TIG welding? Discover the essential equipment required for TIG welding with our comprehensive guide. From the welding machine to safety gear, we cover everything you need to know to get started or refine your TIG welding setup.

What Are the Pros and Cons of TIG Welding?

Tungsten Inert Gas (TIG) welding is an acclaimed welding technique known for site precision, cleanliness, and versatility. Its major benefit lays in its ability to provide highly controlled, neat welds on a vast array of materials.

TIG welding is ideal for thin materials and detailed work making it popular amongst professionals working with smaller and decorative projects.

While TIG welding does indeed have some advantages, it comes with its own set of challenges. It requires a high level of skill and intense focus, particularly when one is steering and feeding the filler materials into the torch.

Such methods can be relatively slower when compared to other welding techniques, making it potentially less efficient for larger scale jobs. The size and complexity of the project at hand can therefore significantly impact the effectiveness of TIG welding.

Protective equipment is a must in TIG welding, as it significantly reduces risks associated with hot works activities, including burns, eye injuries, and exposure to fumes.

The Main TIG Equipment Components

The components required for TIG (Tungsten Inert Gas) welding are numerous, each having a specific role making them crucial. The key equipment consists of a power source, a torch, and an electrode.

The power source uses an electrical current to provide the maximum output necessary for the welding process. It plays a crucial role, and it precisely manipulates electrical flow to control heat, making for a smoother, cleaner weld. On the other hand, the torch has a twofold function.

Firstly, it presents a comfortable and safe user interface. Secondly, the design of the torch allows for precise directional control of the electrical current. The electrode is another essential component that is used to direct the electrical current towards the metal workpiece—generating an arc. Specifically, in the TIG setup, a non-consumable tungsten electrode is used. This electrode doesn't melt during welding, providing consistent, high-quality welds with superior finishes.

Other supporting equipment tends to be utilised in TIG welding as well, such as a shielding gas cylinder, a welding mask, gloves and other safety gear, a filler metal for adding material (if needed), as well as tungsten sharpeners to maintain the electrode in its best condition. In summary, each component of a TIG welding setup is vital, working in unison to make the process possible whilst ensuring safety and quality in the end product.

Gas shielding is a crucial part of the welding process. This procedure is needed to shield the workpiece from exposure to atmospheric contamination, which can adversely interfere with the integrity and strength of the weld. Atmospheric gases such as nitrogen, oxygen, and hydrogen can negatively influence the weld area if not adequately shielded.

Backing systems also play a significant role in the welding process. They provide the essential backing, acting as a foundational layer that helps create a more robust and reliable weld. They provide stability to the weld pool, consequently preventing any sagging or drooping while the weld is being made. Moreover, inserts are a valuable resource in the process too.

These are used to form the root bead in the TIG (Tungsten Inert Gas) welding process. They help achieve a concise and clean weld, particularly at the root, this enhances the overall quality of the weld, making it more resilient and sturdier. Each piece of the welding process is as essential as the other. Each plays its part to ensure a successful, strong, and long-lasting weld.

Safety represents an absolute priority when it comes to TIG welding. Thus, all personal protective equipment, including helmets, gloves, and specially designed 'shielding' clothing, are crucial aspects of TIG welding equipment. These items serve as a first line of defence against potential injuries related to heat exposure, sparks, and ultraviolet radiation produced during welding tasks.

Welding helmets protect the face, neck, and particularly the eyes, from extreme light and potential burns. Meanwhile, gloves safeguard the hands against heat and sharp objects. Similarly, shielding clothing is designed to guard the body from heat, sparks, and spatter produced during welding.

Incorporating these safety measures ensures the well-being of the welder. When appropriately used, they significantly minimise the risks of burns, eye damage, and other potential injuries associated with welding tasks. Proper safety should always be upheld as an essential routine, not an optional choice. Hence, it's vital always to use suitable protective equipment when welding. Remember, in welding as in life, your safety is paramount.

Other Tools You May Require

Tungsten Inert Gas (TIG) welding is often regarded as one of the most versatile and precise forms of welding. However, state-of-the-art technology also requires a variety of additional tools to deliver flawless results. To prepare and shape your electrode, a grinder is a key tool.

Similarly, a wire brush is needed to ensure the weld surface remains clean and uncontaminated. Clamps are useful tools as well, they secure the workpiece and ensure stability whilst welding.

Another essential tool in TIG welding is the filler rod. This tool is used to fill the joint, and bringing a wire cutter along can prove handy for chopping filler rods to the required length. Nevertheless, welding isn't just about having the right operational tools, safety in the workspace is paramount.

Fire extinguishers and first-aid kits should always be within reach. You never know when an emergency could arise that would require their use. Therefore, it goes without saying, having these safety tools nearby can save lives.

In this way, being prepared and equipped not just with main welding tools but also with safety measures ensures efficiency and safety in completing the task at hand. After all, quality work can only be delivered when the environment is safe and prepared.

What are the different types of TIG welding?

TIG welding, also known as Tungsten Inert Gas welding, is a versatile and precise welding process that can be deployed in various applications, and is often further split into two key types: Direct Current (DC) and Alternating Current (AC) TIG welding. DC TIG welding implements a steady current flow, making it ideal for working with certain materials.

Specifically, it excels when used on stainless steel and carbon steel because these materials require a clean, precise weld that DC TIG can offer. This process concentrates the heat in a single direction, making it the preferred choice for maintaining control over a straightforward, deep weld. On the other hand, AC TIG welding utilises a current that changes direction periodically.

This makes it the appropriate selection for non-ferrous metals like aluminium which requires a high energy level to initiate the welding process. Because aluminium forms an oxide layer when exposed to air, the positive half cycle of AC TIG welding breaks down this layer, allowing for effective welding.

DC and AC TIG welding, despite their differences, are vital components of TIG welding. Each offers unique advantages making them ideal for specific materials, thus enhancing the versatility of the overall TIG welding process. No matter the material or the requirement, there's a type of TIG welding to suit the task at hand.

How to Select Tungsten for TIG Welding

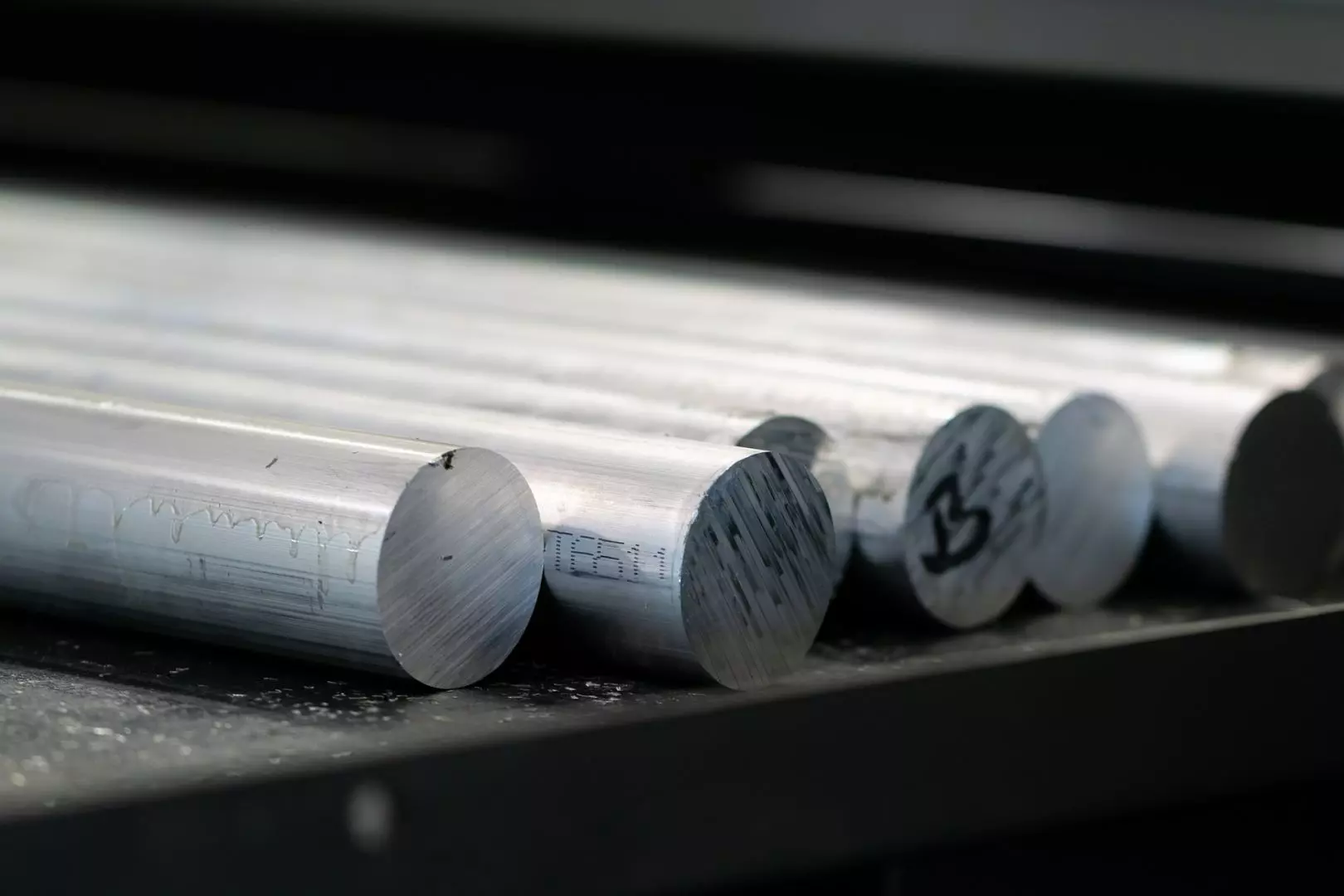

When it comes to TIG welding, the choice of tungsten is influential on the end result. Nowadays, many welders prefer using non-radioactive thoriated tungsten which has excellent ignition and welding properties. There are different types of tungsten, including ceriated, lanthanated, and zirconiated, each suitable for a particular material.

Please remember, the diameter of the tungsten should correspond to the thickness of the material and the power output from the device. If you're working with thin materials and less power, a smaller tungsten would be appropriate. Conversely, a larger tungsten is the preferred choice when dealing with thicker materials and a higher power output. This is important to ensure an efficient and safe working environment.

Are you looking for TIG welding equipment suppliers in Coventry and Warwickshire. Contact our welding equipment specialists working across Coventry, Rugby, Oxford and the surrounding areas.